1

STAGE

A requirements consultation takes place with the client. Scrutinising the levels of protection, and unique provisions that need to be included in the design.

Halliday Finch, specialize in the meticulous process of enhancing vehicle protection levels, in line with security requirements and clients budget, enabling seamless movement in hostile environments, in order to protect life.

The Halliday Finch facility in the Capital of Moldova, Chisinau, is perfectly located to rapidly armour civilian vehicles and move them anywhere in the world they are needed. Our base vehicles are sourced from leading automobile manufacturers, allowing us to utilize their international service networks for acquiring standard OEM replacement parts.

1

STAGE

A requirements consultation takes place with the client. Scrutinising the levels of protection, and unique provisions that need to be included in the design.

2

STAGE

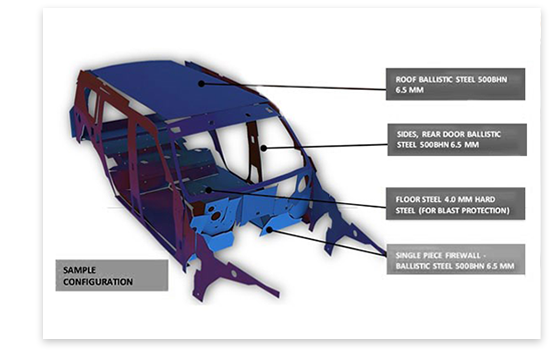

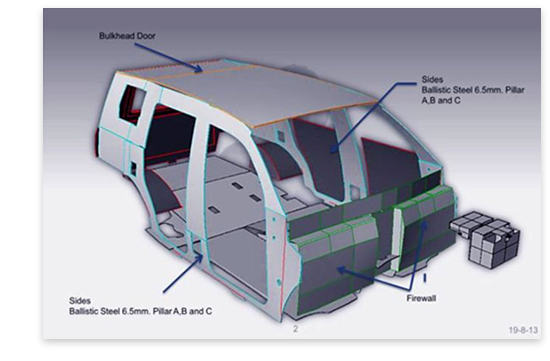

The vehicle’s interior is completely dismantled down to the Frame. All the interior parts of the vehicle are separated and numbered, assigning each part so not a single screw is misplaced. Measuring takes place for the floor, ceiling, doors, and firewall, enabling us to cut and construct the pieces of ballistic material to the millimetre.

3

STAGE

The fuel tank with ballistic nylon is upgraded and it is covered with a water-resistant coating. Conurrently the suspension and braking systems of the vehicle are modified to support the added weight due to the armouring.

4

STAGE

The batteries are covered with high-grade materials, as well as the fuse box and ECM are also covered with protective ballistic steel.

5

STAGE

The Transparent arnour or bullet-proof glass windows are installed. These are specially crafted to fit OEM window channels, providing them great factory finish.

6

STAGE

High-performance and tested run-flat-tire inserts are mounted to the vehicle and any additional options according to the needs of the client, that include power sources, sirens, intercom system or air-bag disconnection.

7

STAGE

The final touches are made to the interior. The vehicle is now fully armoured offering our client the level of protection they require.

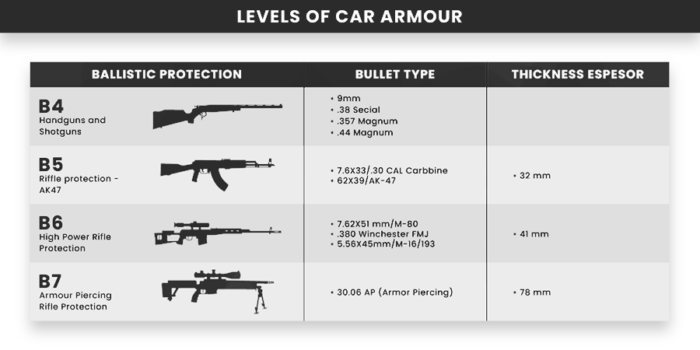

Vehicles with the B6 level of armouring are armoured using materials, both opaque and transparent, that meet or exceed the requirements of the European CEN 1522/23 and CEN 1063 standards to the level FB6 for opaque areas and BR6 for transparent areas.

Our Security Vehicles in B6 level are armoured using materials, both opaque and transparent, that meet or exceed the requirements of the European CEN 1522/23 and CEN 1063 standards to the level FB6 for opaque areas and BR6 for transparent areas..

Our Security Vehicles in B6 level are armoured using materials, both opaque and transparent, that meet or exceed the requirements of the European CEN 1522/23 and CEN 1063 standards to the level FB6 for opaque areas and BR6 for transparent areas..

All four sides of the passenger compartment and the roof of the vehicle are protected using high-quality armour steel and glass defeating 7.62x51mm M80 Nato Ball ammunition (U.S. NIJ level III, CEN level FB6/BR6) and 5.56×45 SS109 ammunition (CEN level FB5/BR5 and FB6/BR6) at 0° incidence (90° to the surface) and 10m range according to CEN1063 and CEN1522.

All four sides of the passenger compartment and the roof of the vehicle are protected using high-quality armour steel and glass defeating 7.62x51mm M80 Nato Ball ammunition (U.S. NIJ level III, CEN level FB6/BR6) and 5.56×45 SS109 ammunition (CEN level FB5/BR5 and FB6/BR6) at 0° incidence (90° to the surface) and 10m range according to CEN1063 and CEN1522.

All opaque areas including the roof are protected against the following and all lesser weapons/ ammunitions at 90° impact angle in accordance with the above specifications.

All opaque areas including the roof are protected against the following and all lesser weapons/ ammunitions at 90° impact angle in accordance with the above specifications.

All transparent areas are multi-layer and polycarbonate coated to protect against the following and all lesser weapons/ ammunitions at 90° impact angle in accordance with the above specifications.

All transparent areas are multi-layer and polycarbonate coated to protect against the following and all lesser weapons/ ammunitions at 90° impact angle in accordance with the above specifications.

The floor of the vehicle is designed to defeat the following hand grenades

The floor of the vehicle is designed to defeat the following hand grenades

Contacts:

Sam Mattock: sam.mattock@hallidayfinch.com or Whatsapp +254724255600